- Home

- Application Solutions

- Fastening on Steel

Innovative solution

For fastening on steel

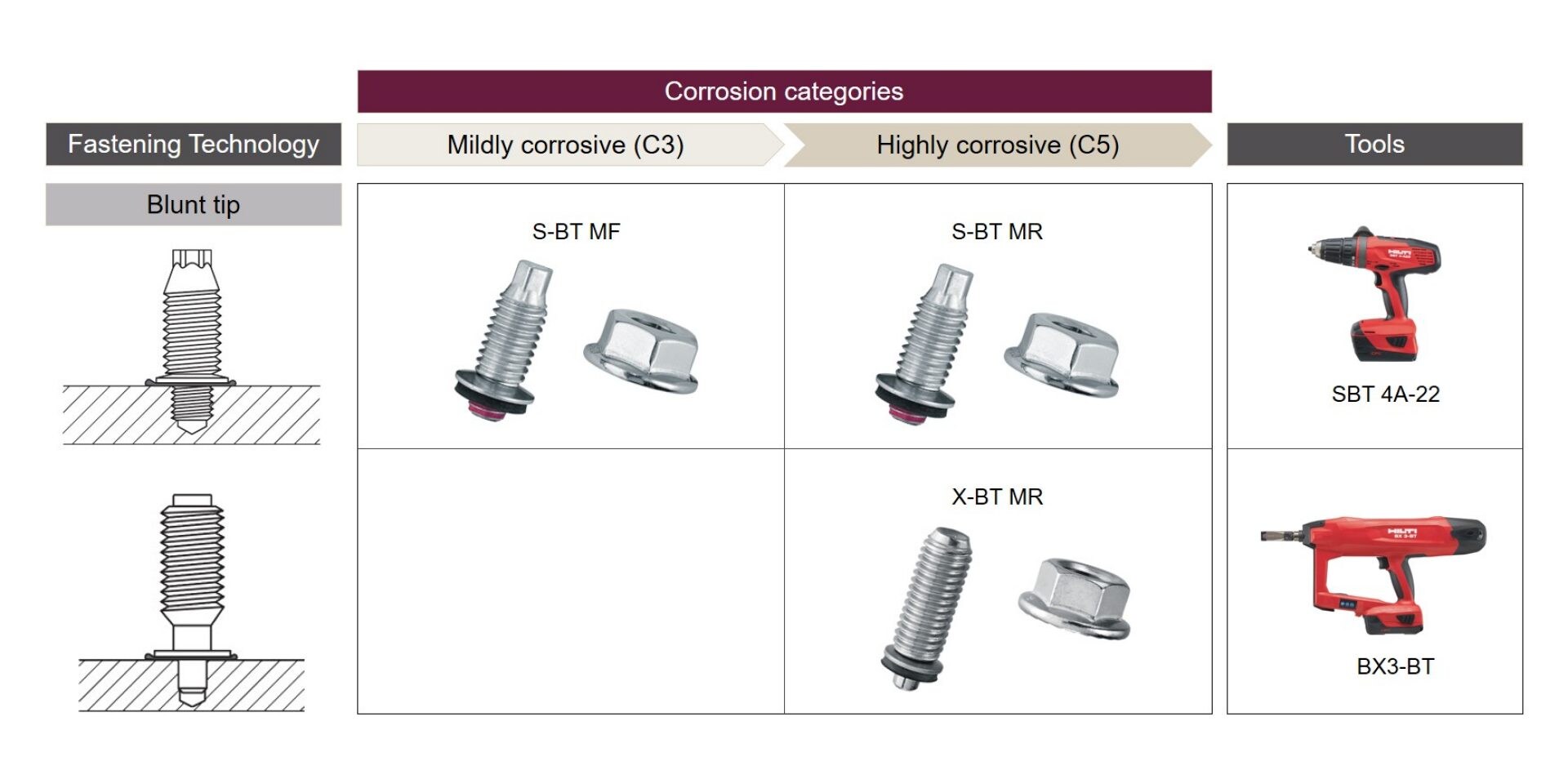

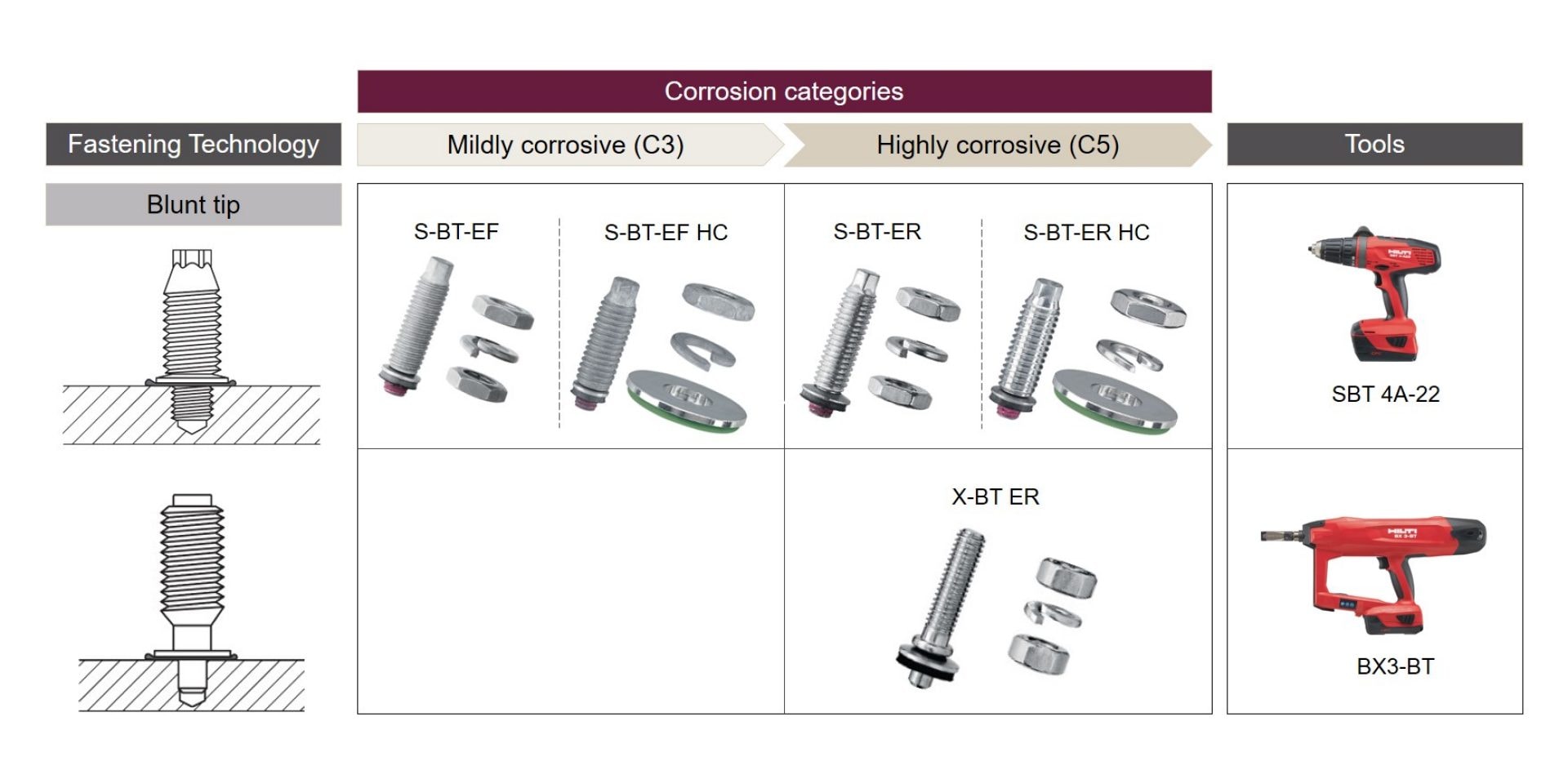

Hilti offers a variety of solutions to various corrosive environments that help reduce or eliminate the drawbacks of traditional methods. Depending on the corrosive environment and type and thickness of the base material, Hilti offers three different fastening options. These solutions help maintain the corrosion resistance of the structural steel and the connection to the non-structural components.

From traditional methods for fastening to steel

1) Welding

- Time consuming preparation of the coated steel e.g. with an angle grinder

- Creates a lot of sparks, which can be a hazard

2) Through bolting

- Drilling process can be time-consuming depending on the thickness and hardness of the steel

- Steel exposed from the drilling must be properly coated to avoid corrosion

3) Clamping

- Limited in direction of attachment of the component since clamps require a specific orientation relative to the structural steel

- Very high material costs, especially for corrosion-resistant clamps in hot-dip galvanized or stainless steel

To fast and reliable ways for fastening to steel

Fixing gratings

- Easy and fast installation for grating fastening

- Fastening gratings to steel structures using the X-FCM-M grating disc or other grating fastener

- Do maintenance with ease

Multi-purpose fastening

- Multipurpose fastening for emergency lamp, modular channels, or any other items

- Quick installation without welding or post paint work

Electrical connections

- Fast and easy installation

- Enhanced protection against static electricity

- Enhanced safety – allows electrical current to flow through the stud and then discharges it properly into the base material

Why make the switch?

Unlike welding or through bolting, Hilti fastening solutions do not require preparation of base material and re-work after the fastening is made. This makes the overall installation much faster, while providing reliable corrosion protection.

Hilti blunt tip fastening on steel can be completed by any trained operator and do not require a certified welder. Therefore, contractors can deploy welders to other critical applications where welding is an absolute must.

Unlike through bolting or clamping, Hilti fastening solutions do not require access to both sides of the steel. This further improves operator safety as there is no need to get fingers into tight spaces.

Hilti sharp tip solutions are for powder-actuated nailers, so can be used under all weather conditions. Cordless drills used for blunt tip solutions are built for tough jobsite conditions, so can be used in nearly all weathers. In addition, the cordless tools are powered by 22V Li-ion batteries so do not require a mains power supply.

Hilti provides comprehensive technical data for different thicknesses and strengths of base steel. This data is backed by International Codes Council’s Evaluation Service (ICC-ES) as well as industry approvals including, but not limited to, the American Bureau of Shipping (ABS). In addition, Hilti blunt tip screw fastening technology has been tested, and is approved for use, in aluminum base material.

Both Hilti sharp tip and blunt tip fasteners are easy to inspect after installation using a visual check or a check gauge.

With Hilti blunt tip technology, fastenings can be completed without damaging the corrosion protection coating, making it ideal for highly-corrosive environments.